Understanding Diecasting: The Course of and Its Applications

Understanding Diecasting: The Course of and Its Applications

Blog Article

Diecasting is a highly-specialized production process that transforms the melting metal into precise elements using high-pressure molds. It has gained a place of importance in a variety of industries, such as electronic, aerospace, automotive, and consumer goods, due to its capacity to create complex forms with incredible precision and consistency. Combining the fundamentals of metallic engineering with cutting-edge technology, diecasting offers unmatched effectiveness and precision. This makes it the foundation of the modern production. This article dives into the complicated world of diecasting, looking at its procedure, advantages in a variety of ways.

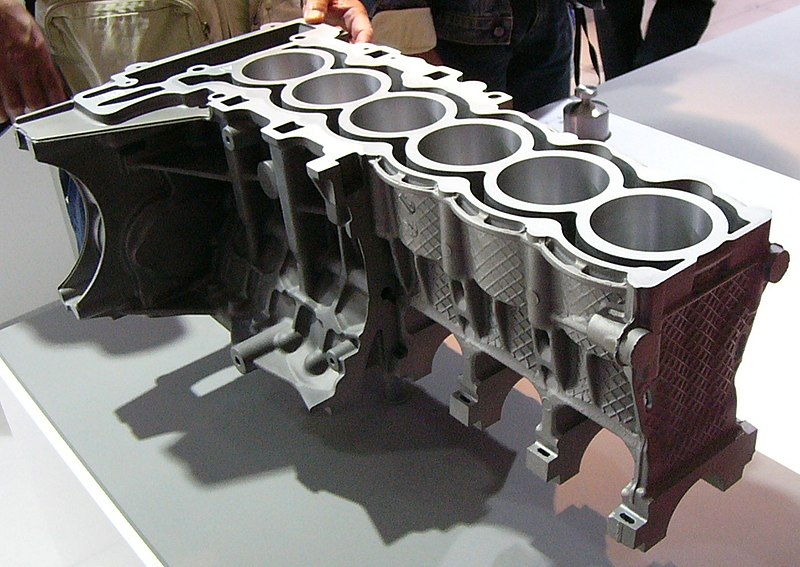

The diecasting process begins by creating the mold, or a die, which is made of hardened steel for a long time to endure high pressures and temperatures. When the mold is made metal alloys, such as magnesium, aluminum, zinc or copper are heated to the point that they melt. The molten metal then gets injected into the die at extreme pressure. This ensures that it covers all the parts of the mold including intricate sections and walls that are thin. This pressure will be maintained until the metal has solidified at which point the die opens, and then the newly created part is released. This high-pressure method ensures that the finished product is accurate without the need for any additional finishing or machining.

One of the main benefits of diecasting is its capacity to manufacture parts with high resolution and precise finish. Injections of high pressure guarantee that the molten material is perfectly shaped in the mold resulting in parts that require minimal machining or finishing. This is particularly beneficial to create complex geometries and thin-walled segments that are hard or impossible to make by other processes of manufacture. Diecasting also produces pieces with tight tolerances as well as great repeatability. It is an ideal method for mass production. The efficiency of the process also leads to cost savings because the higher rate of production reduces labor costs and material waste.

Diecasting can also provide significant advantages in terms of mechanical properties. Components produced through diecasting typically exhibit excellent strength and durability because of the fine-grain structure that is formed by the quick melting of the metal. Diecasting makes them suitable for any applications that require high performance and reliability. In addition, the process allows to incorporate thin walls and complex elements without compromising structural solidity. This feature is especially useful in aerospace and automotive industries, where reducing weight while maintaining strength is critical. It is possible to make light, but strong parts helps improve fuel efficiency and performance of aircrafts as well as vehicles. To find more details please visit https://www.senadiecasting.com.my/

The material used for diecasting has a significant impact on the characteristics and functionality of the final product. Aluminum is a popular choice due to its outstanding strength-to-weight ratio, resistance to corrosion, as well as its electrical and thermal conductivity. These qualities make aluminum an ideal choice for aerospace and automotive uses where weight reduction is a major concern. Zinc alloys provide high strength and ductility. This makes them appropriate for products that need fine details and durability. Magnesium alloys have the tiniest weight of metallic structural elements, offering the advantage when weight reductions are essential. Copper alloys are more rarely used they are highly valued due to their excellent electrical conductivity as well as their resistance to corrosion. Each one of them has its own advantages, allowing manufacturers to select which one is best suited to the application they are looking for.

Diecasting is a sophisticated manufacturing process that combines precision, efficiency as well as versatility. Its capability to manufacture complex, high-quality components with superior mechanical properties makes it useful in a variety of sectors. Diecasting's effectiveness for mass production, together with its material and cost benefits, underscores its value in the modern world of manufacturing. In the future, as industries demand quality and reliability components that are high-performance and components, diecasting will continue to be a cornerstone technology, driving forward the development of innovative products that fulfill the constantly changing demands of the market. Due to its continuous development and applications, diecasting exemplifies the intersection of engineering excellence and manufacturing prowess.